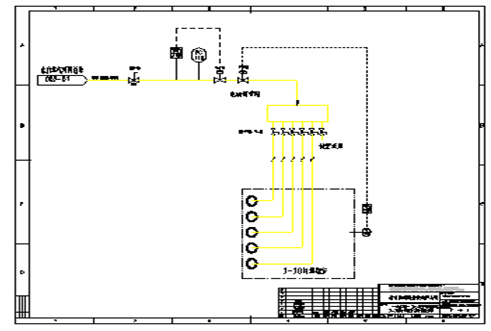

Application case 7: Graphite electrode baking control system scheme

一. Baking control system for graphite electrode

1. Overview of granite electrode baking furnace

Combustion apparatus and controlling system of granite electrode baking furnace are used for 2 sets of baking furnace for 36. Baking furnace are ring type one with cover. Combustion apparatus include gas burning furnace, connected vessel hood (smoke removal frame) and equipment for detecting temperature and pressure, automatically regulate and measuring gas. Each furnace chamber has 5 combustors. There is1set of combustion apparatus and automatic controlling system.

2. Controlling method

Using an adaptive prediction optimization control of modern control theory

3. Technical requirements for system operating

Systems of 11 chambers operate at the same time and the combustion period for each system is36~48h. Temperature for the gas inside the baking furnace is 1050-1250℃. The final temperature of the product in the baking furnace is 850-950℃.

4. Fuel types

Gas, heavy fuel oil, heating gas (or cooled coal gas)

5. Technical parameters for baking furnace.

|

No. |

Project name |

Index |

|

1 |

Number of chambers |

36/set |

|

2 |

Number of workbin (gas well) |

5/chamber |

|

3 |

combustor |

2/chamber |

|

4 |

Period for moving oven chambers |

36~48h |

|

5 |

Temperature for the gas inside |

1050~1250℃ |

|

6 |

Final temperature of the product |

850-950℃ |

|

7 |

Size of workbin |

3900(L)×780(W)×4340(H)mm |

|

8 |

Filling coke |

3~12mm metallurgical coke |

|

9 |

Product standard |

699x525x(3500~4000) 544x475x(3500~4000) |

|

10 |

Distribution of each set of flame system |

16 chambers |

|

11 |

Heating chamber |

3 |

|

12 |

Preheating chamber |

5 |

|

13 |

Cooling chamber |

4 |

|

14 |

Loading and maintaining chamber |

4 |

二、 Basic technical requirements and quantities supplied (each burner

)

1. Natural gas burner(flow meter, nozzle): 5/chamber

The highest combusting temperature of fuel gas:1050-1250℃

The final temperature of product:850-950℃

Connecting method of metal hose of combustors: 600 mm, 360sets

Fine tuned valves (2 inches): 36 sets

Flow transmitter (2 inches): 1set

Safety solenoid valve (2 inches): 36 sets

Buffer tank of gas: 108m rectangular tube

Ball valve (2 inches): 36 sets

Check valve (6 dm): 216

Gas filter: 1 set

Number of equipment sets: (180X2) set

2. Connected vessel hood (smoke removal frame) (manual butterfly valve included)

Temperature of gas: 700℃

Measuring range of pressure: -400~0Pa, on-site examination with ball valve

Number of equipment:3 /set

Connected vessel hood valve use DLVD

3. Temperature measuring equipment

Gas inside the furnace: temperature measuring range:0~1600℃,temperature can transmit far away

Gas at the bottom of the furnace: temperature measuring range: 0~700℃, temperature can transmit far away

Funnel temperature measuring range: 0~700℃, temperature can transmit far away

Number of thermocouple and temperature variation: 41 sets

4. Control system

It requires central and local duel control. Basic function of central control system of computers include display, set, control, save (data within a year), data processing and alarming. When the center controls the system fault, the local control system can maintain production according to the set index.