Application case 8: Automatic control scheme of graphitization

1. Direct current graphitization furnace automatic control program

1.1mechanism of graphitization

Baking carbon products have physicochemical properties and strengths, but carbon atoms are irregular in structure alignment. Products without superior quality performance of graphite should be processed at the temperature of higher than2300-3000℃. This is the fundamental principle of graphite. Graphitizing products:

Improved the heat-conducting property and conductivity of carbon products;

Enhanced the chemical and thermal stability of products and reduced impurities;

Improved the abrasion resistance of products;

Reduced the hardness and made precise machining easier.

1.2Principle of graphitization furnace:

According to the Joule-Lenz's lawQ=0.241I²Rt,namely current add heat to objects through resistance. Products loaded in the graphitization furnace are heating units and also heated units. Heat of resistance is directly proportional to the square of current. The larger the current is, the more the heat will be. The temperature of the furnace will be higher. Graphitization resistance furnace requires low voltage and large current to achieve high temperature to graphite. Electrical characteristics are negative.

In the current cycle, the furnace resistance varies with temperature rising and falling, late to electricity, the electric current to the largest, furnace core is about 1/10 ~ 1/20 of the early, the size of the resistance of graphitization furnace with filling material types, processing temperature, particle size, furnace charging pressure, the size of the circuit section and the length of the furnace, baking electrode itself resistance, and electrode furnace charging mode, and bus bar, conductive electrode, the influence of factors such as contact.

2. Direct current graphitization furnace automatic control program

2.1 control mechanism

(1) Dc graphitizing furnace automatic control system scheme is based on the graphitization furnace its electrical properties is a negative resistance feature/time curve, namely according to the current at the time of the current, voltage, power, power factor and power consumption to control the graphitization

(2) Given in certain electricity situation, the shorter time is sending by graphitizing furnace, the temperature rise of the farthest, can achieve the higher the temperature is, slow if electricity, we get the opposite result.

(3) Based on the power consumption of unit weight products to adjust the voltage, current, according to the size of the products, the furnace charging situation, determined to power value, per hour up power size, calculate the distribution curve, and of graphitizing furnace according to the curve of voltage and current control.

(4) Set up power/time curve library, may choose to call in the future production, save the trouble of repetitive data entry, avoid data error problems

(5) System has a failure, accident, the function of recognition, judgment, by manipulating the images and sound and light alarm alert operators, so that the confirmation and processing; In the high voltage transformer, rectifier device when an accident, according to the setting of the system can automatically stop in advance and ensure the safety of personnel and equipment

(6) Action for all operating personnel, equipment status, such as current, voltage, temperature, pressure signal, has the real-time and historical records.

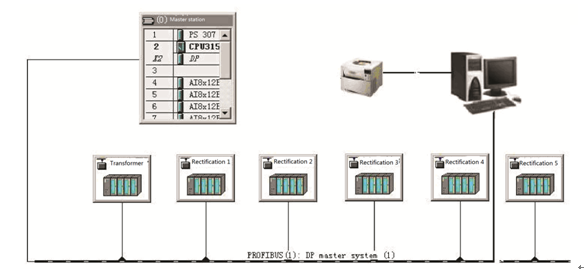

2.1 Automatic System Configuration

2.1.1 Network Configuration

Strong signal according to the electromagnetic interference of graphitizing furnace site of the actual situation of the resistance to electromagnetic interference ability strong FROFIBUS - DP high-speed industrial bus distributed I/O system, and at the same time the system time response effect is good.

2.2.2 Host computer

China industrial control PC using inquiry, and configure a printer

1) A control curve library, users can set on the upper machine, set up and online adjusting control curve, and can be deposited into a curve in the library

Is equipped with process flow, can display the high voltage load switches, transformers, have position, water-cooled large current switch, silicon controlled rectifier (quick fuse), and other equipment, alarm, the state of the picture; Can display the current voltage, current, temperature, and can set alarm value and query historical records.

DC graphitizing furnace control system network configuration diagram

3) There is the function of soft hand, operator interface through the upper machine, adjust the rectifier voltage, current and intervention

4) The operator through the upper machine can implement rectification device system or single device to start, stop and stop

5) All operating records for the query;

6) Through a printer can produce reports.

2.2.3PLC

Use the Siemens S7-300 variable programmable device, ET–200Mdistribution remote station distribution, the high voltage rectifier transformer, load switch unit (contain), deputy transformer, rectifier, oil-water cooler for data acquisition and control etc.

2.2.3.1 Transformer sub-station

Acquisition of high voltage of a voltage, current, power factor, working condition, dc operating voltage signal and its implementation of switch control

Acquisition of transformer temperature, the gas load switches, position, oil and water cooler temperature signal, load switches to have at the same time, oil and water cooler control, achieve on-load voltage regulator and transformer cooling

2.2.3.2 Rectifier sub-station 1

Test the switch state of water large current switch, through the control to the series-parallel transformer secondary voltage.

2.2.3.3 Rectifier sub-station2~4:

Inspect the status of quick fuse, cooling water pressure, temperature, cooling water to flow signals, etc

2.2.3.4 Rectifier sub-station5:

For the controlled silicon to do the phase shifting triggering Angle control, namely do the stepless regulation for voltage and current of graphitizing furnace.

2.2.4 Soft:

PLC programming software STEP7 V5.1;

Upper software (man-machine dialogue software) of Siemens WINCC V5.1

2.2.5 Characteristic of direct current graphitization furnace automatic control program

This control system has high control precision, which can save the heavy manual labor, and accelerate the transmission speed greatly, product quality and production efficiency, saving energy over 10%.

3. Scope of supply

We provide all control equipment of the control system In addition to high voltage, transformers, oil and water cooler, rectifying device, cables, and are responsible to train the operators.

4. Data provided by the manufacturer

High-voltage board, transformers, oil and water cooler, rectifying device, technical parameters of detection instrument equipment, drawings, manuals, etc. So that we can accurate configuration I / 0 points and control equipment selection, and carry on accurate quotation.