Application case 10: The Application of Robust Multivariable Predictive control applied in heavy oil catalytic cracking unit of Qianguo refinery

Program introduction:

Awarded the Second Prize of Technology Progress and the Excellent Paper of Sinopec which published on Automation in Petro-Chemical Industry

Abstract:

Robust multivariate predictive control’s application in heavy oil catalytic cracking unit of Qianguo oil refinery achieved success and the anticipated goal.

The following is a detailed description of the structure and realization of the system.

Key words:

APC RMPCT RFCC

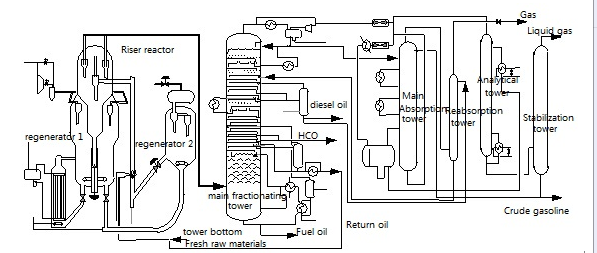

Qianguo oil refinery RFCC adopted the technology of improving tubular reactor and catalytic cracking of internal and external heat removal, blending and vacuum residue. The annual processing capacity is 800,000 tons after they are put into production since 1990. After several years’ overhaul and technological transformation, the device attained the design capacity in processing, blending, yielding of light oil and energy consumption.

1. Residue Fluid Catalytic Cracking

2. Principle of Robust Multivariable Predictive Optimize Control Technology

2.1Basic Construction

It consists of RMPC with optimizer and IRC (intermediate control) and can deal with complicated control object which are too difficult or unable to handle by conventional PID. IRC is an application among RMPC and conventional PID, which can improve the control stability of basic control layer and lower the consumption of public work and recover more energy to increase economic benefit. IRC deals with conventional PID, which needs complex process calculation and consists of complicated control loop. HEONEYWLL has heat duty control, ratio control of steam and product (raw material or catalyst), nonlinear liquid level control, robust PID control.

RMPC(Robust Multivariable Predictive Control consist of multiple-input multiple-output, model based, predictive ability, optimization function which can control and optimize highly coupled industrial process. RMPC controller combines with dynamic model controlling industrial process. According to the model, RMPC can forecast the expected situation and decide how to regulate the controller output, maintaining all manipulated variable on set point or constraint dimension. If they still have degree of freedom, internal optimizer will regulate the output of controller and take the process to the optimal state in line with economic target.

It is difficult for conventional PID single loop to achieve trim control since it is mutual independent between loops, high coupled in variables and there are dynamic trends that loop have large lag and nonlinear or reverse respond. RMPC is the right tool dealing with complex dynamic process. RMPC gathered those important variables in the process and recognize the dynamic model which represents the process. RMPC controls the process as a whole not simple combination of a number of intersected single circuits. RMPC can analyze and solve the coupling relationship among variables. With forecast, it can regulate when the discreet value of controlled variable instead of current value surpass the limit value.

RMPC has built-in optimizer, which works based on the dynamic model of the users’ defined the objective function. The economic objective function here is the combination of linear and quadratic term of the RMPC controlled variables and operating variables. Economic objective function can also be defined by specifying the coefficient of the linear and quadratic term. With the economic objective function, RMPC can take the process to the optimal point once the controlled variables can meet with the control target and the controller still has degrees of freedom.

2.2Constitution of RMPC

2.2.1Control variable

RMPC controller control this type of process variables in order to maintain it in a certain value or within a certain range, called a controlled variable (Control variables), namely the CV.

2.2.2 Manipulated variable

RMPC controller regulate this kind of process variables to keep the CV value in the set point or a certain range required by the personnel, and to make the process to meet the economic objective function determined by the optimization point change, called operation variables (Manipulated Variable), namely the MV.

2.2.3 Disturbance Variables

Due to some restrictions, RMPC controller can't handle this kind of variable but the change of the process variables have obvious effects on CV, and the change can be measure, known as Disturbance Variables, namely the DV.

2.3Features and Functions of RMPC

1) In the process of a typical RMPC control, some CV or even all of the CV are interlinked, so RMPC controller must coordinate the action of multiple MV making a specific CV change the expected quantity in the expected direction without causing other CV have unexpected change.

2) The operator can change the set point or upper and lower range of the CV, and can switch to any other two control ways. Operators can set operational range of the MV, and which represents constraint RMPC controller and optimal controller of the process, equipment, or security will transfer this MV out of the range. when a CV value breaks the limit, RMPC controller will control action according to the model and the setting parameters of the CV. Optimization function will begin to work if it still has a degree of freedom

3) Operators can remove some CV or MV without stopping the RMPC controller when technology, instrument or equipment makes CV can't control or a MV cannot be used. If a CV or MV configures as key variables, RMPC will automatically shut down the controller when these variables have malfunctioning. If the operator to remove these CV or MV, RMPC will automatically shut off the controller.

4) RMPC forecast the effect of the change of DV on CV through the model and regulate MV prevent CV transfinite in advance. DV have feedback effect on RMPC.

5) When RMPC met all operation indicators of CV, and a degree of freedom is greater than or equal to zero, it can make MV be used to meet the economic target. When the degree of freedom is less than zero, RMPC hasn't met the needs of operation indicators of CV.

6) Degrees of freedom = unconstraint MV number - (set-point control CV number + over-limit CV number)

7) RMPC controller has strong robustness, which can overcome error of dynamic model which has big error, and can also control process variables with highly coupling relationship.

8) RMPC has friendly interface, which is consistent with the standard of TDC3000 and provides operators with rich help information. It also has forecasts and adjusted value of MV of the controller in each execution cycle, showing the past trends and forecast future trends of variable

3. Hardware and software environment

3.1Hardware

Our factory RFCC adopts Honeywell TDC3000x collecting and distributing control system as a platform, equipped with application module AxM (can run in TDC3000x environment, and also run in the UNIX environment bidirectional application module, 8 mw memory) as an advanced control platform. All of the advanced control applications are installed on the AxM. With model files installed in AxM UNIX environment, it can solve the problem of the communication on the LCN and make the application of our APC works well.

3.2 Software

APC software require TDC3000X version as R320, our application platform of R500 meet the requirement of the APC.

1) RMPCR146.03, realizes the robust multivariable control function

2) RMPR146.03 identification, realize the identification function of process model

3) RMPC application software has a robust PIDR300, R2.0 FCCU package, fractionating column package R3.0, TDC3000 data collector, nonlinear liquid level controller, heat load controller and so on.

4. APC application

4.1realization process of advanced control

Application of advanced control roughly can be divided into several steps:

1) install RMPC system software and application software

2) configure process calculation of APC

3) design and configure IRC control loop

4) step response

5) recognition and file generation of process model

6) configure RMPC

7) debug and put into operation

4.2Application of advanced control technology

1) computation of technological parameters

2) intermediate controller (IRC)

3) anti/re RMPC controller

4) RMPC controller of the main fractionators

5) absorb stability RMPC controller

4.3Computation of technological parameters

In order to achieve stable process control and optimization control of some process parameters cannot be measured directly in the process, will need to be calculated by other variables can be measured in heavy rush of advanced control application, there are some calculated input variables for the APC, it provides a process for operation personnel and production management personnel information, help them to better understanding of the process, improve the management level of equipment.

Table1 Computation of technological parameters

|

Name of calculated point |

Introduction |

Name of calculated point |

Introduction |

|

MCONV01 |

Calculation of conversion rate |

F213_PM |

Yield of oil thick liquid |

|

RXSEV01 |

Calculation of reaction severity |

HVY_PRD1 |

Forecast yield of heavy oil |

|

R105_Q |

Calculation of outside heat removal |

F208_90 |

Calculation of dry point of gasoline |

|

CATCIRC1 |

Calculation of catalyst recirculation |

F209_95 |

Calculation of dry point of light diesel oil |

|

F310_PM |

Forecast yield of dry gas |

F209_FL |

Calculation of flash point of light diesel oil |

|

F314_PM |

Forecast yield of liquid hydrocarbon |

F209_PP |

Calculation of pour point of light diesel oil |

|

F209_PM |

Forecast yield of light diesel oil |

F312_RVP |

vapor pressure of stabilized gasoline |

|

F312_PM |

Forecast yield of gasoline |

F314_C5 |

Content of liquid hydrocarbon C5 |

|

COK_PRD1 |

Forecast quantity of catalyst coke-burning |

GAS_C3+ |

Content of dry gas C3+ |

4.4IRC intermediate controller

1) FFC107 catalyst stripping steam ratio and catalyst circulation control

Control goal is to maintain the stripping steam and catalyst circulation rate constant. When the riser feeding and conversion rate change, wait for raw catalyst of carbon content is constant, stable operation and helpful to the reaction/regeneration.

2) QC204 fractionating column in the middle loop heat load control

Main fractionators middle circulation in central heat load affect the fractionating column temperature distribution, is an important operation control LCO quality variables, it is to control the light diesel oil solidifying point vital to the quality index.

3) QC203 fractionation tower circulation heat load control

Main fractionating tower circulation heat load mainly affect the upper part of the main fractionating column temperature distribution, the most main is at the top of the column temperature, the impact that affects the quality of gasoline do this indicator, it is an important operation variable control gasoline quality.

4.5anti/re RMPC controller

4.5.1 anti/re RMPC control object

a. Improve the fresh raw material processing: RMPC technology forecast in a timely manner and process improvement of capacity constraints, adjust the/operating conditions again, so as to achieve the purpose of improving capacity.

b. Improve device light: RMPC could adjust completely against/again and operating condition in the bottom of fractionators, and improve the ability of heavy oil conversion, to improve light receiving purpose.

c. Improve the anti-interference ability of device: the/interference property of raw materials, raw materials mainly comes from fresh preheating temperature and the change in the flow back to the oil refining and regeneration characteristics of fluidized bed. RMPC uses the functions of feed forward forecast and feedback correction to enhance the anti-interference ability of device.

4.5.2 anti/re RMPC control strategy

Reverse/again is a fast and strong coupling process, based on the above goal almost all the control means considering the RMPC, RMPC all variables

Table 4 Anti/re-controller variables

|

CVS index |

introduction |

F314_PM.PV |

Forecast yield of liquid hydrocarbon |

|

TI121.PV |

Dense-phase temperature |

F209_PM.PV |

Forecast yield of light diesel oil |

|

TI116.PV |

Dilute-phase temperature |

MVS index |

introduction |

|

AR101.PV |

First oxygen content |

FRC201.SP |

Fresh feed |

|

AR102.PV |

Second oxygen content |

TRC107.OP |

Flow of terminator |

|

PDR107.PV |

Differential pressure |

FRC207.SP |

Flow of recycle oil |

|

ZI101.PV |

Location of plug valve of vertical tube |

TRC201.SP |

Preheating temperature |

|

ZI105.PV |

Location of regeneration valve |

TRC101.SP |

Outlet temperature of lift tube |

|

DRC1101.PV |

Density of outside heat removal |

FRC109.SP |

Flow of second main air |

|

PIK102B.OP |

Revolution of aerostatic press |

TRC231.OP |

Control output of bottom temperature |

|

LR207.PV |

Liquid level of recycle oil tank |

PRC102.SP |

Reaction settler pressure |

|

TRC231.PV |

T201 bottom temperature |

PRC101.SP |

First pressure |

|

TI155.PV |

Second dense-phase temperature |

PRC103.SP |

Second pressure |

|

TI144.PV |

Second dilute-phase temperature |

DRC1101.OP |

Density of outside heat removal |

|

RXSEV01.PV |

Calculation of reaction severity |

FRC205.SP |

Flow of slurry oil |

|

PDRC106.PV |

Differential pressure between reactor and reproducer |

FRC231B.SP |

Flow of output slurry oil |

|

TRC107.PV |

Middle temperature of lift leg |

FRC206.SP |

Return flow of recycle oil |

|

ZI107.PV |

Location of half-regeneration valve |

DVS index |

introduction |

|

R105_Q.PV |

Load of outside heat removal |

FRC1101.PV |

Flow of outside wind removal |

|

PDR108.PV |

Differential pressure of regeneration valve |

FRS003A.PV |

Flow of wind |

|

LIC201.PV |

Liquid level of T201 |

QC204.PV |

Middle thermal load of fractionating tower |

|

TIC228.PV |

Tray temperature of T201 |

FRC207.PV |

Flow of recycle oil |

|

F310_PM.PV |

Forecast yield of dry gas |

TRC101.PV |

Reaction temperature |

|

F312_PM.PV |

Forecast yield of naphtha |

PRC102.PV |

Reaction pressure |

According to the features of our factory, control functions are divided into several connected sub-functions as follows:

1) Control of regenerator coal-burning

2) Control of lift tube severity

3) Control of bottom fractionating tower

4) Control of differential pressure and valve location

5) Yield limit control/simple target control

Use RMPCT functionality provided by the designed controller model again, according to the dynamic response of the CV with MV and DV model, at the same time operating 14 to 25 MV CV process requirement set point or constraint range, and use the six DV PV value of feed forward control. RPMC controller of linear optimizer and coordinate all MV movement range forecast dynamic control algorithm, make the operation meet setting the optimization goal.

5. Effect of advanced control technology

After a year’s operation, advanced control has been accepted and favored by operators, which demonstrates that advanced control have good effect. They are expressed in following several aspects:

1) Greatly improved the stable rate of the device

2) Improved the acceptability of product quality

3) Improved the product yield of the device

4) Lowered the energy consumption of the device

6. Economic benefit of application of advanced control technology

After putting-in-service proactively advanced control, not only improve the level of our factory process control, and bring great economic benefits for our factory every year. The whole device control smoothly obtained very big potential benefits, and reduces the energy consumption of the device. The RMPC controller make the optimization of the reaction depth again bring economic benefits increase the yield of the product. Fractionation and putting-in-service proactively absorption RMPC controller not only ensures the stable product quality, and high value-added products yield improved the economic benefit.

Table 7 Comparison table of economic benefit before and after the application of controller

|

Content

Item |

Unit Price RMB/ton |

Yield before % |

Yield after (1998.10.27-1998.11.10) Annual handling capacity by 800,000 tons |

|

|

Yield difference % |

Annual yield difference Ten thousand |

|||

|

liquid hydrocarbon |

1129.53 |

10.76 |

-0.13 |

-117.47 |

|

gasoline |

1650.7 |

46.26 |

1.83 |

2416.62 |

|

Light diesel oil |

1513.81 |

24.18 |

-0.98 |

-1186.83 |

|

Slurry oil |

721.07 |

5.84 |

-0.42 |

-242.22 |

|

Amount |

|

100 |

|

870.04 |