Application case1: The anode baking control system.

1 overview

This paper describes the technology and characteristics of professional combustion Robust Multivariable Predictive Optimization automatic control System (RMPO) of Beijing CIMAC technology Co., Ltd.

Study Combustion theory and control theory, research, and based on research results to design or modify the furnace so as to achieve energy-saving emission reduction, improve furnace service life and maintenance repair costs and achieve the purpose of saving electricity. Combined with the joint efforts of company control experience in software and industrial technical staff for many years and the East China Sea Aluminium Inc technical staff, with advanced robust, prediction, optimization, adaptive (learning) theory, developed a set of new anode baking Robust Multivariable Predictive Control System optimization. Temperature and pressure system on the baking furnace preheating and baking zone box, fire way of effective cooperative control, the technological requirements of the heating curve and the pressure range of carbon blocks in a tank of preheating, baking, cooling. Fuel oil (gas) development of baking furnace automation control, the whole system runs normally, the technology is advanced and reliable, reached the international advanced level. The quality of this technology in the production of carbon anode product stability, physical and chemical indicators qualified, fully meet the requirements of the customers, creating significant economic benefits for the enterprise, has a very good extension value.

The RMPO system in the development of national science and technology development fund 1500000 Yuan to support, anode baking Robust Multivariable Predictive Optimal automatic control system project is being reviewed by the national patent bureau, the system has taken the lead in Shandong Nanshan Group Aluminium Inc 120Kt/a room 36, East Sea aluminium 54 rooms and 36 rooms Carbon Factory Project investment, control system room 36 anode baking furnace with Germany Inova company in the Australian Bureau of Aluminium Corporation 2 flame system for technical cooperation, achieved the desired effect, the system is suitable for natural gas or natural gas furnace.

1.1The baking control system of RMPO

1.1.1 The system is simple and reliable

☆The system required to use to achieve the best anode baking equipment (zero pressure frame, no automatic cooling, all the necessary sensors, such as user configurable zero pressure frame);

☆Elaborate system equipment, mature, reliable performance (burner, thermocouple, valves etc.);

☆The usage rate is high (more than 99%); low repair rate;

☆Moving characteristics of flame system is convenient and quick.

1.1.2 Combined regulating fuel input and negative pressure

Regulation by cooperative fuel input and / or negative pressure, system can realize the asphalt smoke basically complete combustion, thereby:

☆ To minimize energy consumption: asphalt volatile = fuel;

☆ In fact no tar emission (COMALCO flue gas purification system of flue gas components measured values can provide);

☆ The temperature distribution of fire: optimization of anode quality.

1.1.3 The Open system

☆ System uses friendly computer software (Window 2000, ORACLE), convenient operation personnel;

☆ The various working conditions and changes in the baking process (such as anode, asphalt content, petroleum coke quality etc.), there are corresponding parameters, can easy realization of coping and optimization process;

☆ Factory management information system is connected with the interface.

1.1.4 The best user support

☆High quality manual (manual, repair manuals, software manuals etc.);

☆Intensive training courses;

☆Uninterrupted after sale service.

1.1.5 Excellent carbon knowledge and experience of CIMAC

☆CMT has a carbon anode production in all aspects of talent;

☆Electrical, automation engineering design can undertake the whole anode plants (calcination workshop, paste workshop, baking furnace);

☆Have expert anode quality aspects;

☆Expertise with anode performance of electrolysis process;

☆With the management of anode plant experienced technical management personnel.

Un-interruptible support operation cost our customers very satisfied with the performance, in the baking control system of low and our engineering and technical personnel.

1.2 Anode Baking and RMPO basic functions

1.2.1Introduction

Carbon anode is made up of coke or natural graphite as raw materials, ingredients, kneading, vibration molding, baking or baking the second process, to form a good electrical conductivity and thermal conductivity, corrosion resistant high temperature and other physical and chemical properties of a series of industrial products, it is widely used in the aluminium industry. According to estimates, each producing one ton of electrolytic aluminium need to consume 0.5 ton of anode carbon block, so as aluminium industry in one consumable carbon anode product quality directly affects the economic benefits to each smelter.

Anode baking is a slow process, sometimes a few hours, sometimes even 1-2 days, and because the charcoal temperature lags far behind the flue temperature. Therefore, in the control process, the temperature control point selection for reference only flue temperature, through the flue temperature control is to indirectly control the temperature of carbon blocks. Meanwhile, preheat zone downstream of the exhaust gas temperature gauge frame and frame for the entire flue negative pressure to make the necessary controls to ensure that the pressure gradient and temperature gradient linkages.

Anode baking quality can be affected by many factors, the best raw anode quality, well-designed anode baking furnace is the premise to get the anode with best quality. Optimum heat transfer conditions will ensure that the best possible quality anode. In order to achieve the best results in the aluminium reduction cell, the anode must be after all the same heat treatment process in order to achieve a consistent high quality. Heat treatment of the anode material optimization, the anode and the anode function of the size formulations, thus firing curve selection is to get the best quality anode.

In the baking plant production process, as other uncontrollable factors, calculate the optimal firing system, regulating the firing process temperature and concentration gradients volatile parameters become critical to improve the quality of the anode carbon blocks. Application of the control system, on the one hand to ensure that all the anode baking curves meet the technical requirements, ensuring quality; we must also ensure that the anode is almost complete combustion of volatiles in the protection of the environment and also to provide a considerable part of the heat roaster, energy saving.

1.2.2 Roasting furnace and flame configuration

Use roaster crane, green anode is placed in a bin,-bin and the space between the anodes cokes filled with granules. Hopper walls are composed of two parallel bricks. Walls middle of "tailgate." This structure is used as "fire road" for gas combustion purposes. Roaster is from of "furnace room" composition, "furnace room" between "side wall" partitions. In the end roaster fire trails are all merged into one called "cross-border" flue structures.

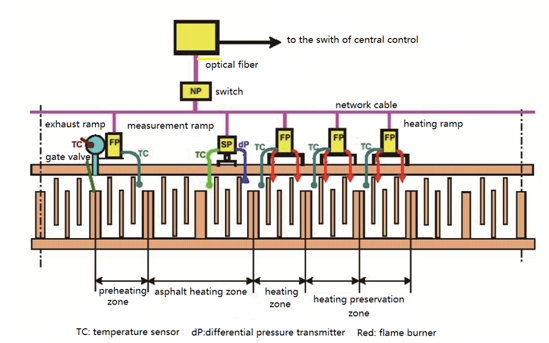

In the forward direction along the flame, each system has a flame burning equipment consists of the following:

Two cooling ramps for cooling the calcined anode

Three burning ramps (each furnace chamber has one). Corresponding to each of the flame path, each aircraft is equipped with a combustion burner and temperature sensors; also equipped with measuring site environment and FP cabinet temperature controller temperature sensor.

One set of negative-pressure temperature ramp. Corresponding to each of the flame path, with a negative pressure sensor and a temperature sensor, equipped with measuring site environment and the SP controller inside a temperature sensor; suction temperature frame is placed in the so-called asphalt combustion zone, namely asphalt smoke burning zone. Roaster combustion asphalt can provide about 50% of the energy demand.

One set of exhaust ramp. Frame through the respective exhaust flue exhaust duct connected with the ring, corresponding to each of the flame path, each aircraft is equipped with a separate exhaust gas temperature sensor and measure site environment, FP controller cabinet, flue gas temperature summarized. Ring attached to the exhaust duct and flue gas purification system, which is equipped with the high-power turbine, can provide a negative pressure required to run roaster. Each one corresponds to the exhaust flue frame legs (bracket), have installed a sliding gate structure used to adjust the level of the corresponding negative pressure flue.

Each flame systems are moved in the direction to the exhaust frame, the furnace chamber for each cycle is generally 24-32 hours. In the roaster during operation, combustion equipment according to the above cycle, each time you move a furnace room. In the same time period, raw anode holder is placed downstream of the furnace in the exhaust chamber while firing is completed and cooled anode travel from the last frame of the seventh burning furnace chamber from the furnace.

Flame travels from flue gas purification system in the smoke pipe ring driven by negative pressure generated. To ensure the safe operation of the roaster should always maintain a negative pressure state. If you lose the negative, then the danger of asphalt smoke including hydrogen concentration will rise, which will result in immediate danger of explosion. To eliminate the risk of explosion, by opening the combustion zone of observation Kong Zengjiang asphalt roaster ventilated and is acceptable.

During the heating process, the following phenomenon may occur.

Between 200-600℃, because of the plastic binder asphalt, raw anode significantly reduced mechanical stability. Filler material functions to prevent deformation of the anode.

At 250-550℃between the asphalt binder will occur chemical reaction (i.e. Asphalt cracking).

The results of cracking of asphalt, the anode will lead to a large number of volatile generations.

Because the negative pressure path of fire, the resulting volatile (asphalt fume) through the filler and the furnace wall into the flue.

If at this time the flue temperature is high enough, more than enough oxygen, the asphalt smoke will burn, namely called "asphalt burning".

In the temperature range of about 600-900℃, asphalt becomes pitch coke. The large number of hydrogen generation.

1.2.3 Anode baking robust multivariable predictive optimization of automatic control systems (RMPO) the basic functions

RMPO basic function is to keep the flue gas set the time / temperature curve. Roaster is a very “slow “system. To go through many hours or even 1-2 days, the anode so as to achieve the flue gas temperature. Thus, the use temperature of the anode baking process control system as a parameter is not feasible. Ideal anode baking curve needs to be transformed into “flue gas temperature target curve." Optimization of the shape of the curve corresponds with baking design, and is a control signal for the system. By a certain time interval, the actual temperature of the flue measured at different locations and comparison with the target temperature. The input energy system through each of the three combustion flame of the burner frame and pitch volatiles combustion provided. The amount of fuel is controlled by the input to the opening / closing means to adjust the burner operation. Exhaust gate structure is used to adjust the shelves negative. Each of the actual negative pressure flues is continuously monitored. Each flame system every path of fire, cloth has five temperatures measuring points. With this information, each of the baking oven chamber acts on the heating or firing process, have been continuous analysis. Through the negative pressure and fuel combined adjusted to achieve optimal adjustment results.

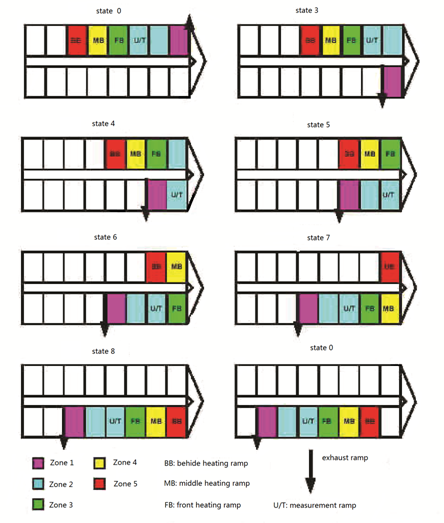

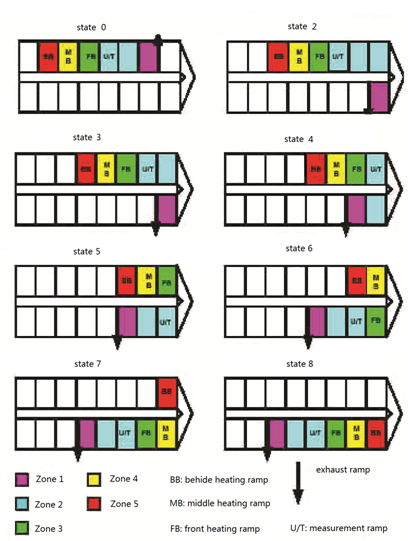

For the purpose of regulation, "active furnace room”, which is located a combustion exhaust frame and the last frame between the furnace chamber, is divided into five “areas." In a six-member (G) consisting of an activity flame furnace chamber system, there is a “zone" by the two furnace chambers, exhaust frame is usually on the second and third furnace chamber, i.e. burning bitumen position.

Basic functions of BakingRobust Multivariable Predictive Optimization automatic control System (RMPO)can be summarized as follows:

◆By setting the temperature curve can run roaster. Not only can run the new roaster, and can run the aging roaster with deformed refractory;

◆Asphalt smoke burn completely,

◆And successfully run "cross flue" state under the roaster, the second way to run automatically.

Crossover operation mode 1 of 6 furnaces’ operation

Crossover operation mode 2 of 6 furnaces’ operation

2. Combustion equipment system description

System communication using advanced , high-performance "star" Industrial Ethernet (TCP / IP) connection layout , on-site fire with RJ45 Cat5e shielded twisted pair backbone using anti-electromagnetic interference capability , long transmission distance optical fiber network structures , 100Mbps transmission speed, which is the communication speed "PROFIBUS field bus ring ," the number of times, and when the control system, once we place any failure does not affect any other parts of the work ; site FP, SP flame processor programmable logic controller PLC selection , good service, more powerful networking features Siemens S7 series PLC has a particularly strong technological advantages step7-300 series CPU314 processor , hardware configuration and flexible, programmable the controller has an RS232 communication port , terminal equipment which supports asynchronous serial data communication at the scene FP, SP flame processors, used for the initial download and lower computer program with on-site operator panel View 1000 's communication between the built over TCP / IP network interface to the programmable controller , the central controller for communication between CP using ether net for data exchange and monitoring .

Carbon Anode 38 chamber baking plant