Application case 14: Shandong Haihua Group chlor alkali resin DCS control system

1. Honeywell TPS System Description

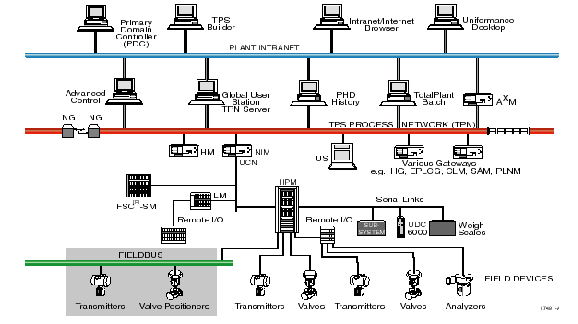

1) System Components Figure Functional Description

HPM on from the design provides a flexible and powerful data acquisition and control functions. It uses a multi-processor architecture; with different processors perform different tasks. HPM includes advanced process management station module (HPMM) and I / O subsystem. Advanced control processor cards complete routine, logical, sequential control functions, while executing user’s CL / HPM program. Due to communication and input and output processing were completed by a different processor, control processor can play it powerful, specialized complete control strategy.

Control functions HPMM provides a number of control functions, for a variety of process automation needs. I / O scan, conventional control, logic control, as well as more advanced control functions, are easily implemented in HPM. Conventional control functions including complex control scheme, chain logic functions and process-oriented engineers advanced control language (CL / HPM).

HPM is the second routine can handle 800 or discrete control loop performance controller. Users can control the configuration of rational organization to meet application needs.

HPM uses a lot of self-diagnostic function, to diagnose health and any faults. Fault is divided into hard and soft faults, HPM status not only in the LED display on the front panel, and in the standard state GUS display screen can be seen. HPM’s any circuit board can be hot-swappable, which greatly facilitates maintenance. When replace AO or DO, the manual operators can maintain output. All in all, HPM has its excellent safety and reliable control performance.

2. TPS System Features

2.1 system openness

The PIN network of TPS system that plant information network (PLANT INFORMATION NETWORK) is using Ethernet. The GUS full operation station of TPS system provides a standard Ethernet interface, integrated management and control whole plant can be easily completed.

LCN, UCN communication has the same development direction with international open structure and industry standards specifications. TPS system has achieved resource sharing (network hardware, system software, application software, databases, etc.), DCS systems and computers, programmable logic controllers, on-line quality analyzer; smart field instruments can perform data communication. Truly open system.

2.2 Human Interface powerful

TPS system uses a full range of user stations (GUS), which is process-oriented single window, using the color image display (CRT) technology, window technology (Windows) and intelligent display technology. Users can design from simple to complex user display for the operator of distinctive operations; each GUS operator station with three attributes: its operator attributes for the operator to monitor the production process and the TPS system itself work conditions; their properties for engineers and software engineers to update the system configuration; their maintenance property for maintenance personnel tracking system operation and diagnose system faults.

2.3 Process Control Powerful

TPS system interface to data acquisition and process control is very wide. It can be dispersed in one or more general purpose control network (UCN) on the HPM process controllers, LM logic controllers conduct, but also from other companies to obtain data on the device, these data apply to all system modules. System control strategy including regular, logical, sequential control, batch control. From the simple to the complex and sophisticated conventional PID control advanced control, production ranges from continuous production to batch production. Applications are involving various production areas. Such as metallurgy, chemical industry, power plants, petroleum, paper and so on.

2.4 System Digital Integration

Honeywell is the first digital communications via a multi- variable field measurement sensors and distributed control system integration. HPM with Honeywell smart transmitter digital integration, the concept of this kind of digital integration can: improve the measurement accuracy, so that the operator can be obtained on a general-purpose operating station within the scope of all variable valuesand Transmitters state. Using a single physical connection supports multi- variable transmitter. HART Communicator does not use smart transmitter configuration. It is providing a complete transmitter diagnostics in general-purpose operating station.

2.5 factory integrated management control integration

TPS System is a large-scale system, it can according to user needs and integrated management of the factory plant information network connected to form a broad range of integrated computer network system to achieve optimal control of complex and sophisticated , the realization of production planning, product development, sales , production process and material flow and information flow on the integrated management , constitute a network of automated factories and enterprises , which constitute a computer-implemented integrated management and control system .

2.6 system safe and reliable, easy to maintain

TPS system in the overall design uses advanced redundant, fault-tolerant technology. There are hardware and software components of error detection and correction, when an error or failure has little effect on system operation or degrade its performance, the system continues to run. TPS system communication network, the interface module is a standard redundant.

Application module AM historical module HM, Process Manager (APM, HPM), Logic Manager (LM), input and output processor (IOP), redundant power supply can be used.

TPS systems are building blocks of the structure, to achieve functional dispersion, dangerous scattered. The database system provides several levels of chain protection; prevent unauthorized changes to the database. System widely used self-diagnosis, self-correcting procedures, standard hardware and software, versatility, online maintenance.

2.7 System Compatibility

TPS TDC-3000 system is developed on the basis of the system, but in the TPS system, the new and old systems can coexist with each module to become part of the system, US and UxS screen display converter can also be converted to GUS on.

3 System configuration instructions

This project uses advanced DCS Distributed Control System TPS (TOTAL PLANT SOLUTION) integrated solutions for plant-wide system that not only in the control layer withstood the industry’s most stringent tests of a variety of conditions, and information management at the company level layer also has the most successful application experience in the Chinese petrochemical, metallurgy, chemical industry produced a huge benefit.

3.1 Configuration Guidelines

• Reliability

All components used in harsh industrial environments through the use of screening and reliable products, all controller modules are sealed packages do corrosion. System all cards from the U.S. origin, the system cabinet from the domestic integration.

• Advancement

The system uses the latest Honeywell TPS integrated management control system, represents the development direction of the DCS system.

• Practicality

System to adapt to the user's requirements and the actual situation, input and output modules with hot plug capability, wiring using crimp terminals, and fully guarantee the system successfully put into operation.

• Openness

The system has good openness, using WINDOWS 2000 operating system, and the addition of TPS-Uniformance module, the easy integration of management and process information.

3.2 System Configuration

The project totally has three sets of TPS control system, respectively polymerization of PVC, VCM, caustic soda plant monitoring and control. The system is independent of the production process to complete networked communications, data sharing capabilities , to achieve cannot be achieved by conventional instruments central display operation , the relevant amount of advanced control algorithms, as well as the harmonization of scheduling and scientific management.

The system due to the use of advanced computer systems hardware and supporting software for complex control algorithms provide high-level conditions. The whole control, display and operation to achieve full digital, full-screen technology to solve the multi-parameter associated control technology object puzzles.

3.3 System Performance Indicators

1) Operating station chief engineer station (full user workstations GUS)

Processor chip level: Intel Pentium IV 2.0 GHz & Motorola 68040

CRT: 21 ", resolution 1024 × 1280

Main memory capacity: 384 MB

2) HM historical module

Capacity: 1.8GB X 2

Access cycle: 5S, 10S, 20S, 30S, 60S adjustable

3) Controller

HPM (controller redundancy)

Concurrent multi-processor architecture: UCN communications processors, I / O connected to the processor, the control point

Processors, redundant control processors, each block I / O cards have brought

A processor, some I / O cards redundant

4) Network

LCN Local Control Network

Speed: 5MB / s

Length: 300M, dual redundant coaxial cable, fiber optic cable expandable to 4.9 kilometers through

UCN Universal Control Network

Speed: 5MB / s

Maximum length: 750 meters, dual redundant coax

5) Controller input / output board

I / O subsystem include redundant input and output links and up to 40 pairs of redundant I / O processor card. These I / O processor card to complete all field I / O signals for data acquisition and control functions. I / O subsystem load design: With maximum I / O points for not more than 40% load capacity.

TPS system for each I / O cards are CPU processor. I / O processing and control processing are completely independent, I / O scanning rate and the I / O count, the controller loads, processing, and alarm contents. The multi-CPU configuration fully reach control processor efficiency and convenience of the I / O expansion.

4 Workshop system solutions

Users should be, equipped with automatic control system combined with our experience, we in the system configuration:

4.1 PVC section

☆Workstation (GUS) 4 units

Both all -round user workstation engineer station and operator station functions, and can be 100% of each preparation , the process in order to achieve the most secure and convenient monitoring.

☆ HPM - High-performance process management station two pairs (control, communications, network and power redundancy)

Control system consists of a high-performance process management station HPM HONEYWELL composition, it is mainly to complete the data acquisition system, regulate and manage the total load rate of over 40%.

☆ HM - historical data management module is a Taiwan

HM is used to recording historical data, access and system resource files for safe storage, dual hard disk redundancy.

☆ Redundant NIM - Network interface module 1 pair

NIM for the operation and control layer network layer network LCN UCN exchange data, the total load factor of 40% or less.

4.2 VCM section

☆Workstation (GUS) 4 units

Both all -round user workstation engineer station and operator station functions, and can be 100% of each preparation , the process in order to achieve the most secure and convenient monitoring.

☆HPM - High-performance process management station two pairs (control, communications, network and power redundancy).

Control system consists of a high-performance process management station HPM HONEYWELL composition, it is mainly to complete the data acquisition system, regulate and manage the total load rate of over 40%.

Even on a hot explosion zone signal processing has the following two programs, the following will be attached equipment list and quotation.

Option I, in the remote explosion-proof zone thermocouple inputs use local I / O, FTA plus the safety fence way.

Option II, in the remote explosion zone thermocouple inputs use local I / O plus the safety fence, and field FTA mode

☆ HM - historical data management module is a Taiwan

HM is used to recording historical data, access and system resource files for safe storage, dual hard disk redundancy.

☆ Redundant NIM - Network interface module 1 pair

NIM for the operation and control layer network layer network LCN UCN exchange data, the total load factor of 40% or less.

4.3 SODA section

☆Workstation (GUS) 6 units

Both all -round user workstation engineer station and operator station functions, and can be 100% of each preparation , the process in order to achieve the most secure and convenient monitoring.

☆ Remote operator station (REMOTE GUS) 2 sets

Remote operator station and the main control room through a state network of local GUS outbound connections were placed on the HCL synthesis and evaporated solid base control room of the sub-station to be monitored.

☆ HPM - High-performance process management station two pairs (control, communications, network and power redundancy)

Control system consists of a high-performance process management station HPM HONEYWELL composition, it is mainly to complete the data acquisition system, regulate and manage the total load rate of over 40%.

☆ HM - historical data management module is a Taiwan

HM is used to recording historical data, access and system resource files for safe storage, dual hard disk redundancy.

☆ Redundant NIM - Network interface module 1 pair

NIM for the operation and control layer network layer network LCN UCN exchange data, the total load factor of 40% or less.

5 summarizes the system input and output points

PVC Section

|

I/O Module |

I/O Points/Unit |

User Specified |

Red. I/O |

Total Requested |

Qty of Modules |

System Provides |

|

HLAI |

16 |

46 |

20% |

56 |

4 |

64 |

|

HLAI(redundancies) |

16 |

121 |

20% |

144 |

9 |

144 |

|

AO |

16 |

31 |

20% |

38 |

3 |

48 |

|

AO (redundancy) |

16 |

39 |

20% |

47 |

3 |

48 |

|

DI |

32 |

477 |

20% |

573 |

18 |

576 |

|

DO Red |

32 |

218 |

20% |

256 |

8 |

256 |

|

LLMUXAI/RTD |

32 |

36 |

20% |

44 |

2 |

64 |

|

DO |

32 |

93 |

20% |

112 |

4 |

128 |

|

Total |

|

1,061 |

|

1278 |

52 |

1376 |

VCM Section

|

I/O Module |

I/O Points/Unit |

User Specified |

Red. I/O |

Total Requested |

Qty of Modules |

System Provides |

|

HLAI |

16 |

208 |

20% |

250 |

16 |

256 |

|

HLAI(redundancy) |

16 |

27 |

20% |

32 |

2 |

32 |

|

AO (redundancy) |

16 |

22 |

20% |

27 |

2 |

32 |

|

DI |

32 |

110 |

20% |

132 |

5 |

160 |

|

LLMUXAI/RTD |

32 |

46 |

20% |

56 |

14 |

448 |

|

LLMUXAI/TC |

32 |

322 |

20% |

384 |

||

|

DO |

32 |

146 |

20% |

176 |

6 |

192 |

|

Total |

|

881 |

|

1061 |

45 |

1120 |

SODA Section

|

I/O Module |

I/O Points/Unit |

User Specified |

Red. I/O |

Total Requested |

Qty of Modules |

System Provides |

|

HLAI |

16 |

368 |

20% |

442 |

28 |

448 |

|

AO |

16 |

121 |

20% |

144 |

9 |

144 |

|

DI |

32 |

458 |

20% |

544 |

17 |

544 |

|

LLMUXAI/RTD |

32 |

51 |

20% |

62 |

2 |

64 |

|

DO |

32 |

338 |

20% |

406 |

13 |

416 |

|

Total |

|

1,336 |

|

1606 |

71 |

1664 |