Development and application of intelligent optimization control system of ceramic tunnel kiln

1.The structure features and technological requirements for tunnel kiln

(1) Structure

Tunnel kiln is 61 meters in length, in which the preheating zone is 21 meters, the firing zone is 15.6 meters, and cooling zone is 24.4 meters. The firing zone has eight sets of burning kilns, the burner uses the completely-hot wind atomization proportion burner, oxidizing atmosphere sintering, the funnel naturally exhausts smoke, the main firing products are series of color glaze ceramic products, and the firing cycle is approximately 20 hours.

(2) Process requirements

According to the process requirements 38 points were set, including 26 points of temperature, 16 points of which is the temperature of combustion chamber, and 10 points of which is the kiln temperature, using thermocouple detection, and using compensation wire signal transmission;

9 pressure points, the control and the detection select micro differential pressure transmitter and Holzer transmitter;

1 points of the oxygen content of the flue gas, using the intelligence zirconia analyzer to display, and send to IPC;

1 point of the oil temperature measuring;

1 point of fuel consumption is accumulating in the IPC.

The control technology indexes of the kiln, about temperature, pressure distribution and the value of excess air coefficient A, demanded by the process of production, as following:

² The furnace temperature 950℃-1350℃;

² 1#~3#combustion chamber a given value of ± 12℃;

² 4#~6# combustion chamber a given value of ± 10℃;

² 7#~8#combustion chamber a given value of ± 7℃;

² Kiln temperature the main thermocouple’s temperature of burning zone is a target value of ± 4℃;

² Kiln pressure the pressure at both ends of burning zone is a given value of + 1.5Pa;

² The oxygen content of the flue gas is controlled in 6~8%;

² Oil temperature a given value of ± 3℃;

² Oil pressures a given value of ± 0.05Mpa.

2. Characteristics Analysis of the object

By analyzing the temperature parameter, which can be expressed as:

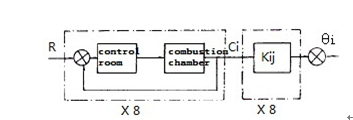

In the formula, Kijis a transfer matrix, describes the transmission characteristics of kiln body, in addition to depend on the structure of the kiln body, also related to the factors such as kiln products, the speed of entering the workshop and so on. The change of Kijis usually accredited to be very small, so we just need to make sure the precision of combustion temperature control, the kiln temperature distribution curve can always be expected. Its control box is seen in fig.1.

Fig. Control cabinet drawings

If the given value of this system is the temperature of each monitoring point (totally 8 points), and given the control point of the value of Rican be adjusted, and then multivariate regulation system can be formed.

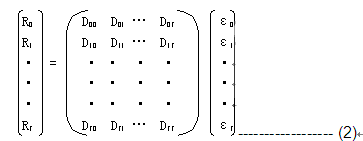

The relationship formula of regulating about the above adjusting system:

Formula: Ri(I=0, 1,…,7) -------- the given value of control point;

εi(I=0, 1,…,7) ------- the deviation between the given value of monitoring temperature and monitoring point

Dij(I=0, 1,…,7) ------- regulation law

Due to the capacity of the tunnel kiln delays large time, control period cannot be less than the sum of the pure lag time plus the measurement lag time. The host computer control system is a sampling control system with variable control period, so it is easy to realize the temperature control.

The above analysis is a more comprehensive description of the transfer characteristics of kiln body and the used adjustment laws, but in the actual process of kiln firing, the mainly role of low temperature furnace is decomposition and oxidation stage, the key parts of determining product firing quality is that each combustion chamber temperature can keep relative stability in the high temperature section. So, taking the single loop constant feedback control can meet the requirements of low temperature furnace, RMPO control is used between the high temperature furnace (No.6, No.7) and the main thermocouple’s kiln temperature, to reach the objective of stabilizing the general guaranteed key.

Relationship between the 6#,7#furnace and the main temperature point can be expressed as:

R6= f (θ6) = a0+ a1ε6

R7= f (θ7) = b0+ b1ε7

Formula: R6, R7is the goal setting value of 6#,7#furnace in both symmetry sides of the kiln body; a0,b0,a1,b1is the transmission system.

The pressure system of kiln relative stability is the key to keep the temperature stable. In general, a kiln with burning oxidation atmosphere, the pressure distribution is micro negative pressure (PY) and micro positive pressure (PZ) at the beginning and the end of burning zone. If ignoring secondary factors and simplifying the system, the kiln pressure (PZ)at the end of burning zone is the result caused by the comprehensive effect of a kiln tail wind (PW), the rapid cooling (Pj), extraction (Pr) and change of fuel combustion gas (△PS), represented by the formula:

Pz= f (Pj, PW, Pr,△PS) ------------------- (3)

when Pj, PW are stabile, we use the change of Pz caused by other factors as the interference of Pr to handle, by adjusting the hot wind output to eliminate the influence of these factors, thus, the positive pressure relationship also can be expressed as a function of single variable: Pz= f (Pr)

Likewise, the regulatory formula of negative pressure can be obtained through the analysis: PF= f (PY)

Formula: PY----- the pressure at the bottom of the flue

PF----- the negative pressure of the furnace (the pressure at the beginning of burning zone).

3. The system structure and working principle

(1) RMPO control system

The system consists of a computer and a PLC or a dedicated controller as the slave computer, its characteristics as following:

① The IPC is the microcomputer application of international standard bus in industrial control, has a wealth of optical electrical isolation interface, high reliability;

② The computer has strong data processing ability, convenient connect into the controller through the communication interface, can realize the field processing of data transmission, parameter modification, man-machine dialogue, and use its abundant software development capabilities to form the control system combined with complete function and simple operation.

(2) Output actuator

①The 16 way temperature control circuit uses the electric actuator, adjusting the nozzle opening, changing the oil to control the combustion chamber to keep given temperature of kiln stable.

②The 2 furnace pressure control loop: the pressure at the end of burning tape uses the electric actuator to adjust the amount of air drawn to control; the pressure at the beginning of burning tape uses electric actuator to adjust the main flue gate opening to achieve;

③The oil temperature, temperature pressure regulates units by installed in the kiln, control fixed value by computer, to keep the oil’s temperature and oil pressure relatively stable;

④The detection circuit of flue gas oxygen, getting oxygen content of flue gas in the firing zone and regulating the combustion air by zirconium oxide analyzer, and then to achieve the best combustion of fuel.

In order to ensure the system operation in the special case, each loop is equipped with automatic and manual switching without disturbance and valve position tracking function.

(3) The working principle of the system

Under the control of computer timer, CPU circularly inspects 38 monitoring points and control circuit at a certain time; signal is transmitted into the field controller, after doing signal adjustment by the amplifier and A/D conversion, through the parallel port input computer CPU to be processed, the result outputs and displays, the control loop sampling data is operated by PID of variable coefficient, outputs controlled Variable to the D/A board as the control signal of valve actuators, adjusts the valves (gate) opening, and then reach given value to process parameters.

二 software design

1. Software structure

The software of furnace control system is divided into two parts, the main program of control algorithm and threshold control algorithm.

2. Some key points of software design

(1) In tunnel kiln, such as the temperature parameter, its characteristic is inertia and capacity lag. the decision of sampling cycle T is the key of control system, which are the main parameters influencing on the stability of the system, the number of previous studies can be described as the first inertia plus the process of delaying time, if the delaying time is t, when T > t, theory has proven, one time of sampling adjustment can be to achieve the system stability, if the total transition time is To, so long as T > To+ t, the closed-loop system is stable and no static difference.

Practice has proved that, the inappropriate selection of T (too big or too small), will make the system dynamic quality deterioration, and even lead to system instability, it should be combined with the characteristics of the object under the guidance of the theory, in the actual operation to tuning. And the kiln relatively temperature of kiln pressure is small lag. During the scene adjusting, we use the change cycle of the kiln pressure as the basic sampling period, and control cycle of the temperature is divided into several stages according to the multiple of the temperature, control mode and the basic sampling period: such as high temperature, low temperature, cascade, in order to control the different furnace temperature. High level control frequency is higher than the low level (the basic sampling cycle is 13 ~ 15 seconds).

(2) Control algorithm using the integral separation incremental control algorithm. The incremental formula:

Un=Un-Un-1=Kp△en+Tien+KD△2en-------------- (4)

Formula:

Kp----- proportional coefficient; TI----- integral coefficient; KD----- differential coefficient;△2en=△en-△en-1= en-2en-1+en-2;△en= en-en-1;en= R-Yn;R------ Setting value; Yn------- sampling average for n.

Incremental algorithm has the advantages that: the computer only outputs the incremental quantities of control, not dramatically changes valve (gate) position, there is little affect even the error operation. But when stop-start or changing the given value, due to big deviation within a short period of time, will cause that the system will appear larger overshoot and longer oscillation in the elimination of error, in order to overcome this shortcoming, the algorithm introduces integral separation, and uses the logic coefficient L, and then the formula (4) turns into:

△Un= Kp△en+L•TIen+KD△2en--------------- (5)

Formula:

E0------ threshold, when en> E0, L=0, integral term is zero, only PDwill regulate; when en≤ E0, L=1, integral will effect. This can reduce the overshoot, the control performance is improved.

三Anti interference measures taken by the three system

1. The hardware measures

(1) The interface board is photoelectric isolation, breaking off the interference on the host from earth wires;

(2) The weak signal received by measuring, using double end input differential amplifier board, effectively preventing the common mode interference;

(3) According to the different types of signals, the one or two meter, respectively using floating and grounding, reasonable wiring;

(4) The power input end is placed an interference suppressor and a high quality switching power supply, to enhance handling of the interference on the power supply.

2. The software measures

The software uses signal to filtering digital, in order to prevent signal error caused by random noise.

RMPOV1.0 control system realizes the monitoring of tunnel kiln, to maintain the best condition of sintering process, so as to improve the product quality, increase productivity, and achieved remarkable economic benefits.